LABORATOIRE DUBOIS S.A.

A.-M.-PIAGET 50 · CP 979

CH-2301 LA CHAUX-DE-FONDS

Tél. + 41 (0)32 967 80 00

contact(at)laboratoiredubois.ch

A.-M.-PIAGET 50 · CP 979

CH-2301 LA CHAUX-DE-FONDS

Tél. + 41 (0)32 967 80 00

contact(at)laboratoiredubois.ch

Tribological tests and lubricant characterisation

In the field of watchmaking and microtechnology, friction consumes a large part of the small energy reserves available.

The development of friction pairs and high-performance lubrication systems considerably improves the service life and reliability of the products.

For example, we perform the following tests with a ball-disc tribometer :

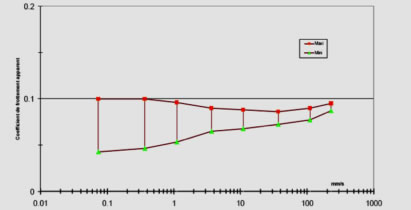

- Dry or lubricated friction tests, in a dry medium or with controlled moisture, with friction coefficient measurement and determination of the wear rate

- Oil lubricity measurements

- Quality control of lubricants-Evaluation of additives

- Lubricant ageing and conditions of storage

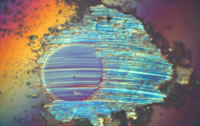

- Wear and service life of materials / coatings

- Characterisation of surfaces before /after tests

Search

PDF en relation

- Lubrification_horlogere.pdf

- Exemple_Etude.pdf