A.-M.-PIAGET 50 · CP 979

CH-2301 LA CHAUX-DE-FONDS

Tél. + 41 (0)32 967 80 00

contact(at)laboratoiredubois.ch

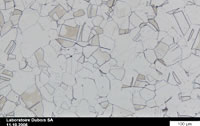

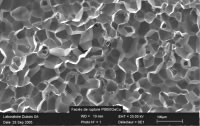

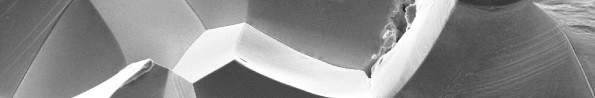

Microstructure examinations

Knowing the microstructure of a material very often makes it possible to understand the production or treatment process of the piece inspected. Its quality can also be assessed, such as the residual porosity of a ceramic or the quantity of non-metallic inclusions in a metal alloy. In addition, the mechanical properties of the piece, such as its hardness or corrosion resistance, are heavily dependent on the microstructure.

So microstructure inspection is an important aspect in understanding the characteristics of a piece. Examples of applications include enhancing a production process, monitoring a manufacturing process or perform a failure analysis.

This control is generally performed using optical or electronic microscopy, after specific preparation. Image analysis is used to quantify the percentage of a second phase or amount of porosity.